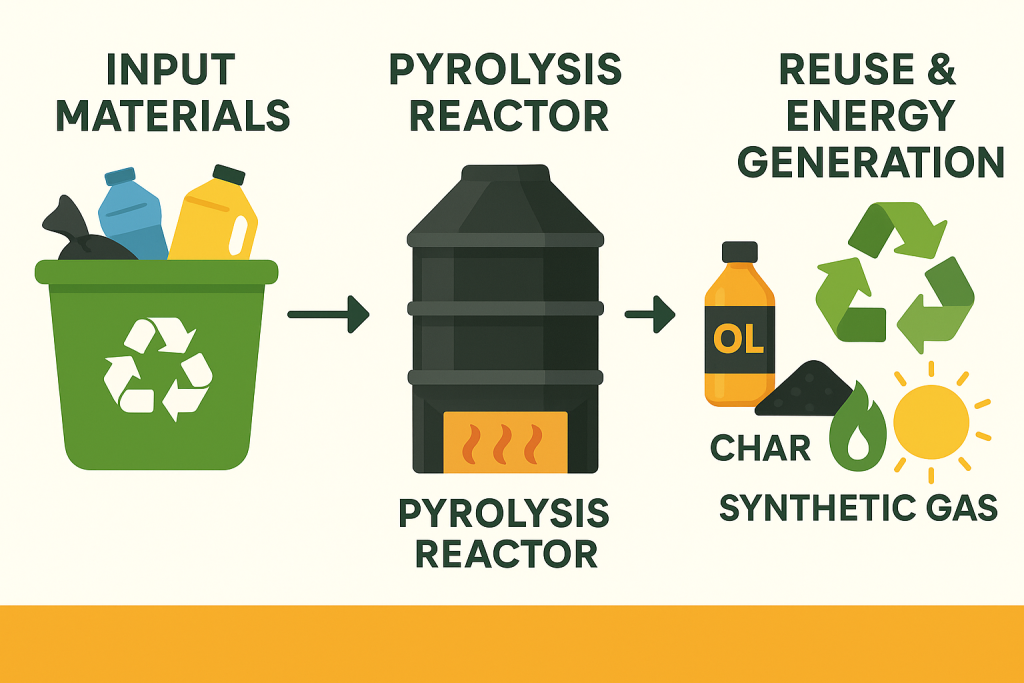

Pyrolysis is a modern waste management technology that breaks down plastic, rubber, and biomass without oxygen, converting them into valuable resources. How It Works:

- Input Materials – Waste like plastic bottles and packaging is collected.

- Pyrolysis Reactor – Materials are heated in an oxygen-free chamber, breaking into simpler compounds.

- Output Products:

- Oil – Can be refined into diesel or used as fuel.

- Synthetic Gas – Used for electricity generation.

- Char – Reused in agriculture or filtration.

✅What is Pyrolysis?

Pyrolysis is a high-temperature, chemical decomposition process that breaks down organic or hydrocarbon-based materials (like plastics, rubber, biomass, and municipal solid waste) in an oxygen-free environment.

Syngas (synthetic gas) for fuel or electricity. Pyrolysis oil that can be refined into synthetic diesel.Char (biochar or synthetic coal), used as fuel or soil additive

The process is self-sustaining: the syngas produced can power the system, minimizing external energy needs and lowering operational costs.

✅ Scientific Summary:

Pyrolysis is an endothermic reaction involving the thermal degradation of materials between 300°C and 900°C, without the presence of oxygen. It preserves the carbon chain integrity of the material, making it ideal for waste-to-energy conversion and circular economy applications.

🌍 Summary: Why Countries Are Choosing Pyrolysis

| Reason | Benefit |

|---|---|

| 🛑 Waste Overflow | Rapidly reduces landfill dependency |

| 💡 Energy Crisis | Converts waste to clean electricity and fuel |

| 🌍 Climate Goals | Low CO₂ solution for carbon-neutral targets |

| 🧪 Resource Recovery | Extracts oil, gas, metals, and carbon-rich materials |

| 🏗️ Scalable Tech | From mobile units to full megawatt plants |

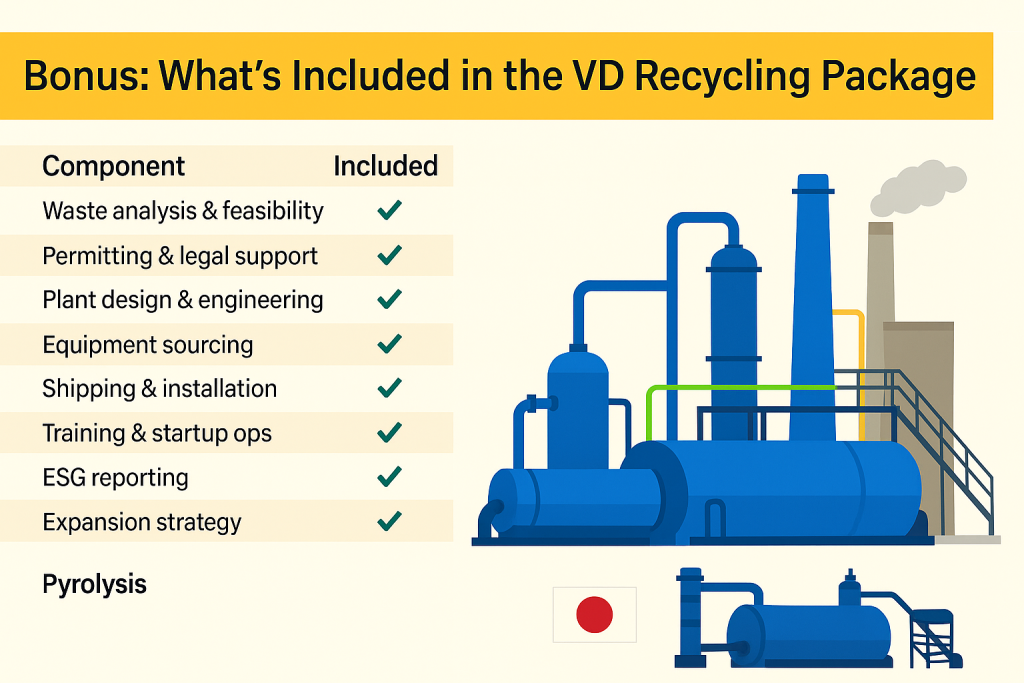

🌍 Steps to Implement Pyrolysis Technology – By VD Recycling LLC

This structured, professional rollout plan is designed for governments, municipalities, and private-public partnerships seeking sustainable waste solutions.

Fully Continuous Pyrolysis Plant

DOING fully continuous pyrolysis plant is developed using three core technologies: low-temperature pyrolysis technology, fully sealed technology and environmental exhaust gas purification technology. It can fully pyrolysis tire rubber powder and plastic particles to produce high value-added products such as fuel oil, carbon black, and steel wire (tires). Fully continuous pyrolysis plant can continuously feed materials and discharge slag, truly achieving 24-hour continuous operation with a high safety and environmental protection factor. It realizes the harmless disposal and resource utilization of solid waste.

Batch Pyrolysis Plant

DOING batch pyrolysis plant uses low-temperature pyrolysis technology to fully crack the polymers in organic waste such as waste tires/rubber/plastics/aluminum plastics/oil sludge and restore them to small molecules or monomer states. Eventually, we can get high value-added products such as fuel, carbon black, and steel wire. There are multiple scales of batch pyrolysis plants for sale, which meet the emission standard and have the advantages of stable&safe operation, long service life, etc.

Waste Oil Distillation Plant

DOING waste oil distillation plant can convert waste engine motor oil/waste lubricating oil/pyrolysis oil/crude oil/liquid oil sludge, etc. into high-value non-standard diesel fuel and asphalt through high-temperature catalytic distillation technology to increase the added value of the product. The color and smell of waste oil/crude oil will be greatly improved, and the diesel yield may reach 80-85%. DOING waste oil distillation plant is equipped with exhaust gas and flue gas purification system to achieve green and profitable recycling of waste oil/crude oil.

Cable Wire Recycling Machine

Henan Doing cable wire recycling machine adopts dry type physical separation method to process waste cables and wires to separate copper from plastic out. The separated copper is as big as a grain of rice, so it is also called cable wire granulator machine.

Raw materials: Waste cables and wires, like power cable, armoured wire, electronic wiring harness, aluminium wire, headphone cable, vehicle wiring, electric wire, copper wire, etc.

Aluminum Plastic Separation Recycling Machine

Aluminum plastic separation recycling machine can fully recycle waste aluminum-plastic composite materials to produce high value-added products, like aluminum and plastic, by adopting dry type physical separation method, which uses no water, no fire, or chemical solution, totally pollution-free. Through crushing, grinding, sieving and electrostatic separation, aluminum can be separated from plastic with the separation rate of 99%, to achieve the purpose of recycling aluminum and plastic again.

Circuit Board Recycling Machine

Circuit board recycling machine is designed for processing waste circuit boards, like computer boards, cell phone boards, printed circuit board, copper clad laminate, etc. Through shredding, crushing, sieving, air separation and electrostatic separation, circuit board recycling machine can not only destroy the data on the circuit boards to protect our privacy, but also separate the precious metals out of resin fiber powder, and the separation rate is as high as 99%.

In addition, DOING circuit board recycling machine is also equipped with pulse and cyclone dust collector, which has no pollution to environment.

Radiator Recycling Machine

Radiator recycling machine is a large-scale crushing and separation line, mainly used to separate copper, aluminum and iron from various waste radiators, such as air-conditioning radiators, car water tanks, condensers, refrigerator broken materials, etc. Through shredding, crushing, negative-pressure baffling separation and air separation, the separation rate of copper, aluminum and iron can reach to 99%.

DOING’s engineers can provide one-stop solution and turn-key project of different radiators and processing requirements, including equipment customization, equipment installation guidance, equipment debugging, and plant design and upgrading.

Carbonization Machine

Carbonization machine (also called charcoal making machine)is used to dispose of biomass waste like wood, bamboo, corn cobs, coconut shells, rice husks, straws, etc. Through drying, carbonization and cooling process, the material is pyrolyzed into charcoal, gas, tar, vinegar, with a carbonization rate of 95%.

The carbonization machine adopts a high-temperature and low-oxygen pyrolysis process to produce charcoal from biomass waste. It is a low-carbon and environmentally friendly equipment with high cost performance and high return rate.